Hire AIR Graduates: Hangar-Ready From Day One

Entry-level talent trained on live procedures and real sites

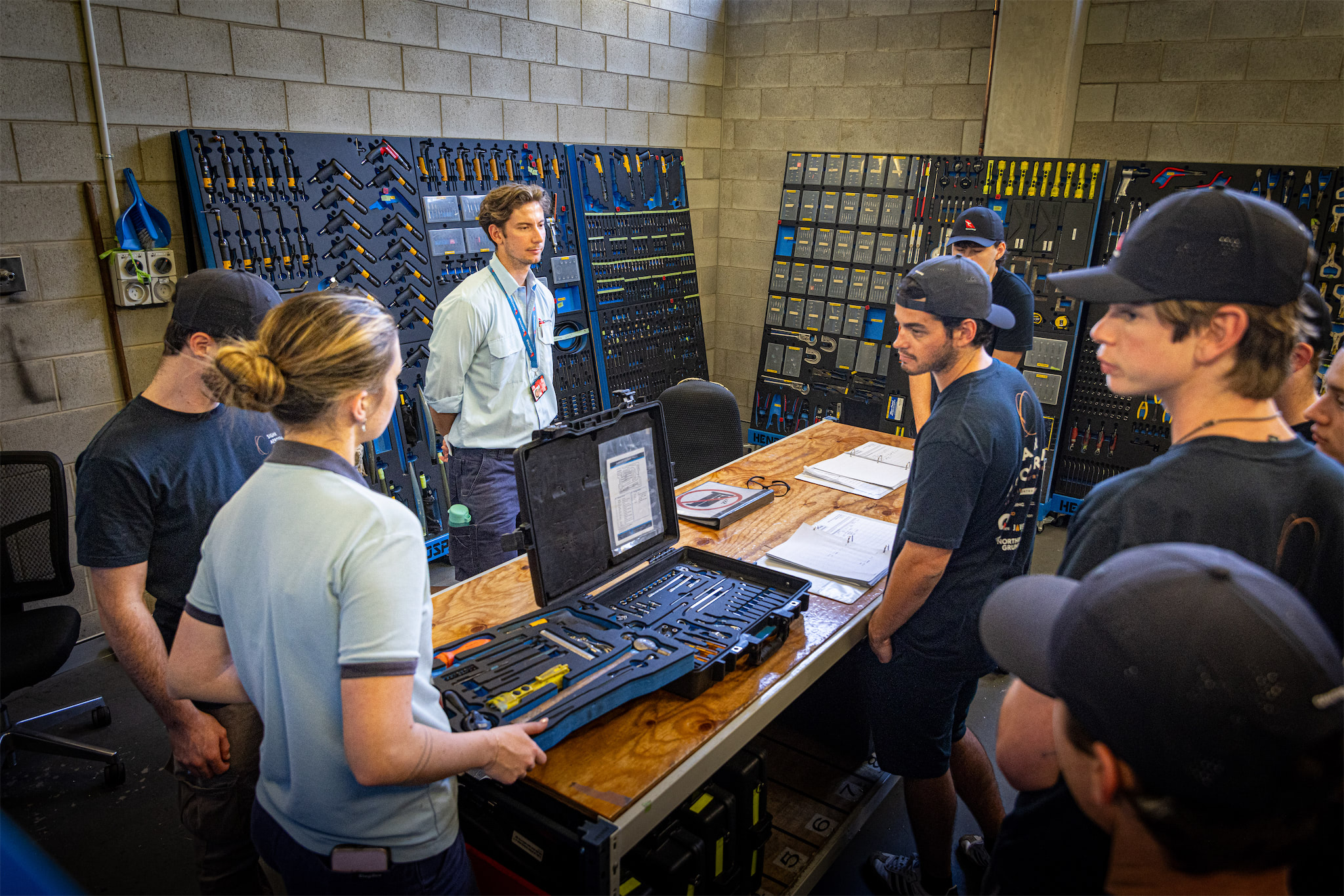

AIR graduates pre-screened with the basics: PPE, tool control, FOD discipline, WHS, HF/CRM, and supervised maintenance practice aligned to industry expectations. They’ve been inside operating facilities, on the line, and have seen how real heavy maintenance works, not just a classroom demo.

They’re comfortable on the flight line and in the hangar, understand inspection points, and follow approved data and sign-off discipline. You’ll spend less time onboarding and more time putting them on productive tasking.

Contact Us to Explore Graduates